You can increase the power of an engine by increasing its capacity. This is a fairly involved process and requires a good deal of research and preparation. Unless you want to have to retrace your steps and go a different route midway in to the job.

Some of TorqueCars.com members have had their engines rebored ,and this does seem a good way to increase power. However there are a few things we should take into account.

Improve safety and braking of your car

Safety Mods "Play it safe." When one starts modifying a car, little thought is usually given to the safety of the […]

Gaining power from the addition of an intercooler on a turbo engine

The advantages of adding an aftermarket intercooler. "Keeping your cool" One problem with a Turbo is the close proximity of […]

More power with an engine swap a simple guide

Engine swaps and transplants. "Insane engine swaps" A popular modification with Torquecars members involves a complete engine swap and remains […]

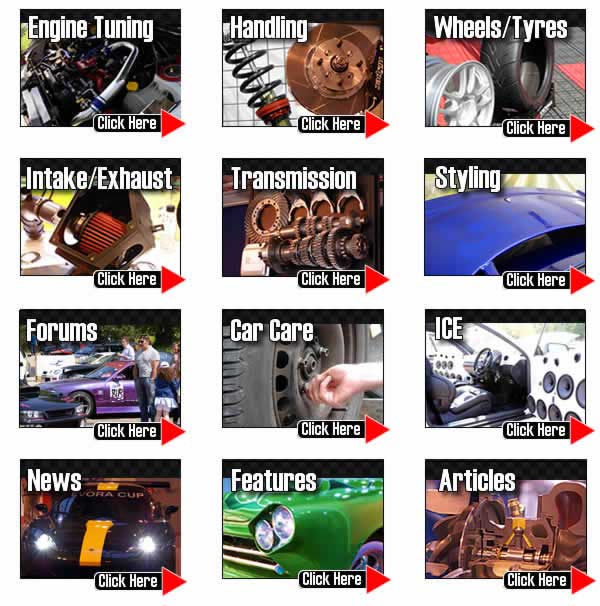

Todays featured car modification articles

Performance Clutches

Clutch tuning: performance clutch modifications and triple plate clutches setup More...